CNC Machines

High speed milling

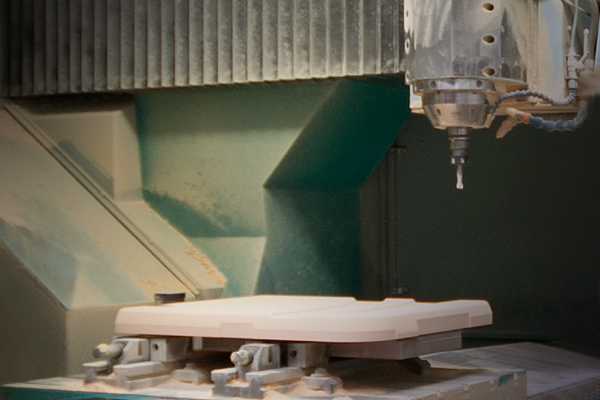

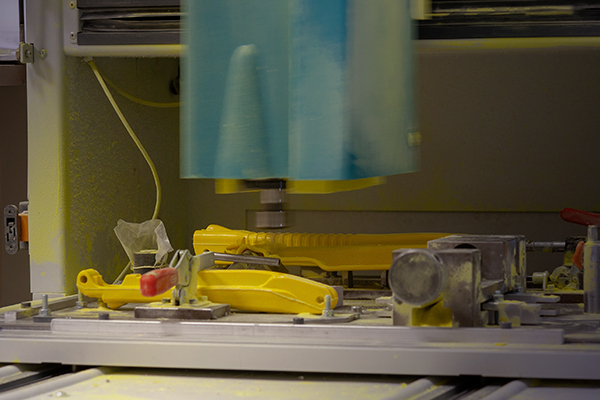

The conventional CNC controlled machines for creating 3D parts are milling machines and lathes. Today High Speed Milling centers are 10 times faster than conventional milling machines in terms of cutting speed (up to 40.000 rpm).

The 3D machining program generates the required cutter paths to the CNC (Computer Numerical Controlled) machine, which then runs an automated process to produce parts by cutting away unwanted material from solid blocks. Multiple axes can work multi-dimensionally to produce highly accurate parts which may be used for functional testing.

By using HSC milling technique and CAM computer system it is possible to obtain the final product with greater accuracy and better polished surface finish.

Finishing processes like coating and painting may be applied to modify the surface even further. Available materials for HSC are aluminium, steel and plastic.

Ideal for

- Producing prototypes of final material

- Creating concept models

- Testing a pilot production line especially in metal

- Producing work equipment

Advantages

Another great advantage of this technique is repeatability; multiple parts can be replicated over extended periods from the same CAD file to the same specifications. Therefore it is ideal for testing pilot production batches.