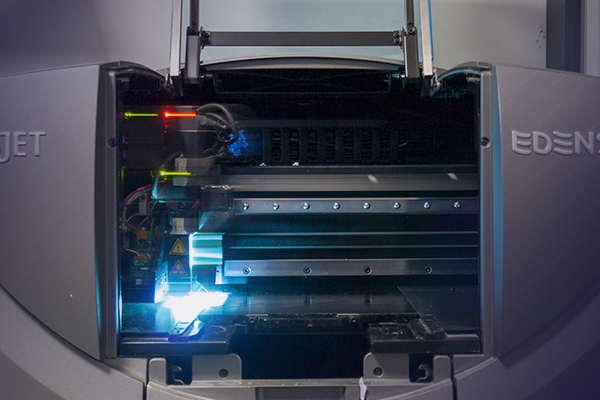

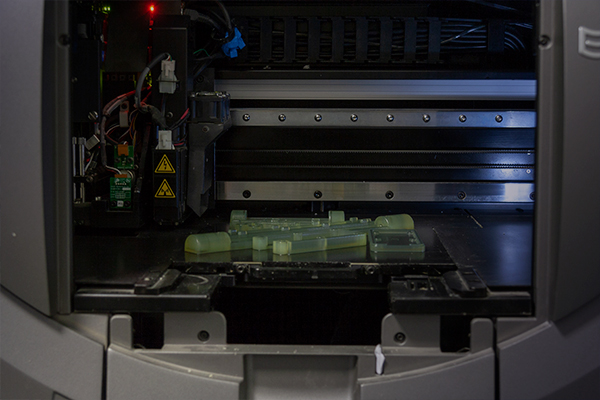

Stereolithography EDEN OBJET / XFA

Stereolithography (SLA)

SLA or stereolithography is an additive manufacturing technology in 3D printing used for creating prototypes, masters and models. Additive manufacturing can be faster, more flexible and less expensive when producing relatively small quantities of accurate parts. SLA prototype is produced from a liquid in a layer by layer fashion using technique called photo-polymerisation. Photopolymers are sensitive to ultraviolet light, so the resin is photo-chemically solidified.

SLA is most suitable for visual applications where a smooth surface finish and a high level of detail are required. SLA also produces a wide variety of shapes, finishes, textures and colour. As a result, functional testing can be initiated early in the design process. At the same time, these prototypes can be used to assess potential customer acceptance.

Stereolitography is ideal solution for creating prototypes of accurate design or for master model in silicone mould. There is a wide range of materials available; durable, rubber-like, clear and temperature resistant to simulate the final design.

Ideal for

- to test and to assess the design of a prototype

- master patterns for silicone mould

- presentation models to verify visual appearance of the product

- prototypes of soft material without silicone mould

DESIGN CHANGES

By using the latest 3D technology there are practically limitless possibilities to create prototypes in variety of shapes and sizes. SLA makes it possible to get extreme dimension accuracy and fine detail. It gives designers and concept development teams the ability to produce parts and concept models easily economically.